Can Space Volume Adversely Affect the Dilution of Contaminants?

What is Air Changes per Hour (ACH)?

Clean air is supplied to indoor spaces to dilute the concentration of contaminants to a certain acceptable level. The requirement for such ventilation airflow rate is generally specified in terms of Air Changes per Hour (ACH). It is a ratio of supply airflow rate (cubic feet per hour or cubic meter per hour) to the volume of space (cubic feet or cubic meter). Therefore the unit of ACH is 1/h. ACH values are generally specified for health care facilities, laboratory spaces, and cleanrooms in their respective standards, codes, and design guidelines. In most cases, these ACH values are based on the consensus of experienced professionals who represent on the codes and standards committees. In most cases, the specifications for ACH lack scientific rationale. The same value of ACH is specified irrespective of the nature of contaminants, their generation rates, and the volume of the space. This leads to a precautionary notion of “more is better” which leads to an excessively large cost for HVAC infrastructure and large cost for operating the HVAC systems for these facilities. There is also a notion that the number of air changes per hour indicates the number of times the room air exchanges with the supply air. This is not entirely true because the flow path of the supply air is not a “single-pass unidirectional” flow from the supply to exhaust. Air takes several circulatory paths in between before exiting the space.

Why Space Volume Matters?

When design engineers require to determine the size of the air handling unit and other HVAC infrastructure they simply multiply ACH values specified in the code, standards, and design guidelines with the volume (floor area x height) of the space. Thus, the supply airflow rate increases with an increase in the floor area and/or height of a space. Note these supply airflow rates are not determined based on dilution calculations, contaminant generation rate, the acceptable levels of contaminants concentration. It simply assumes larger spaces require more air for dilution.

We performed Computational Fluid Dynamics (CFD) analyses to verify the impact of the current practice of specifying the same ACH for all space volumes on the dilution levels of contaminants.

CFD Analysis for Predicting Dilution Levels of Contaminants

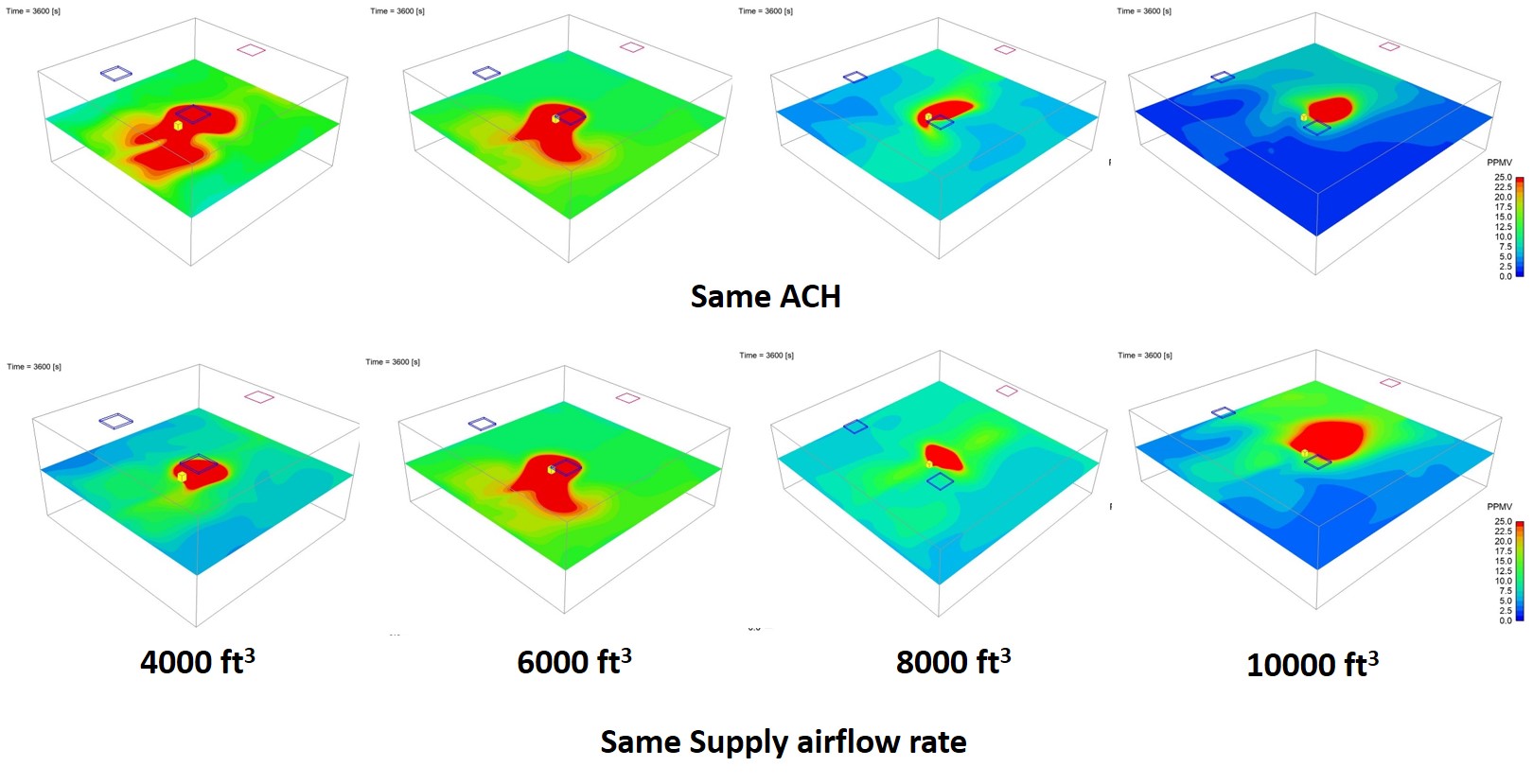

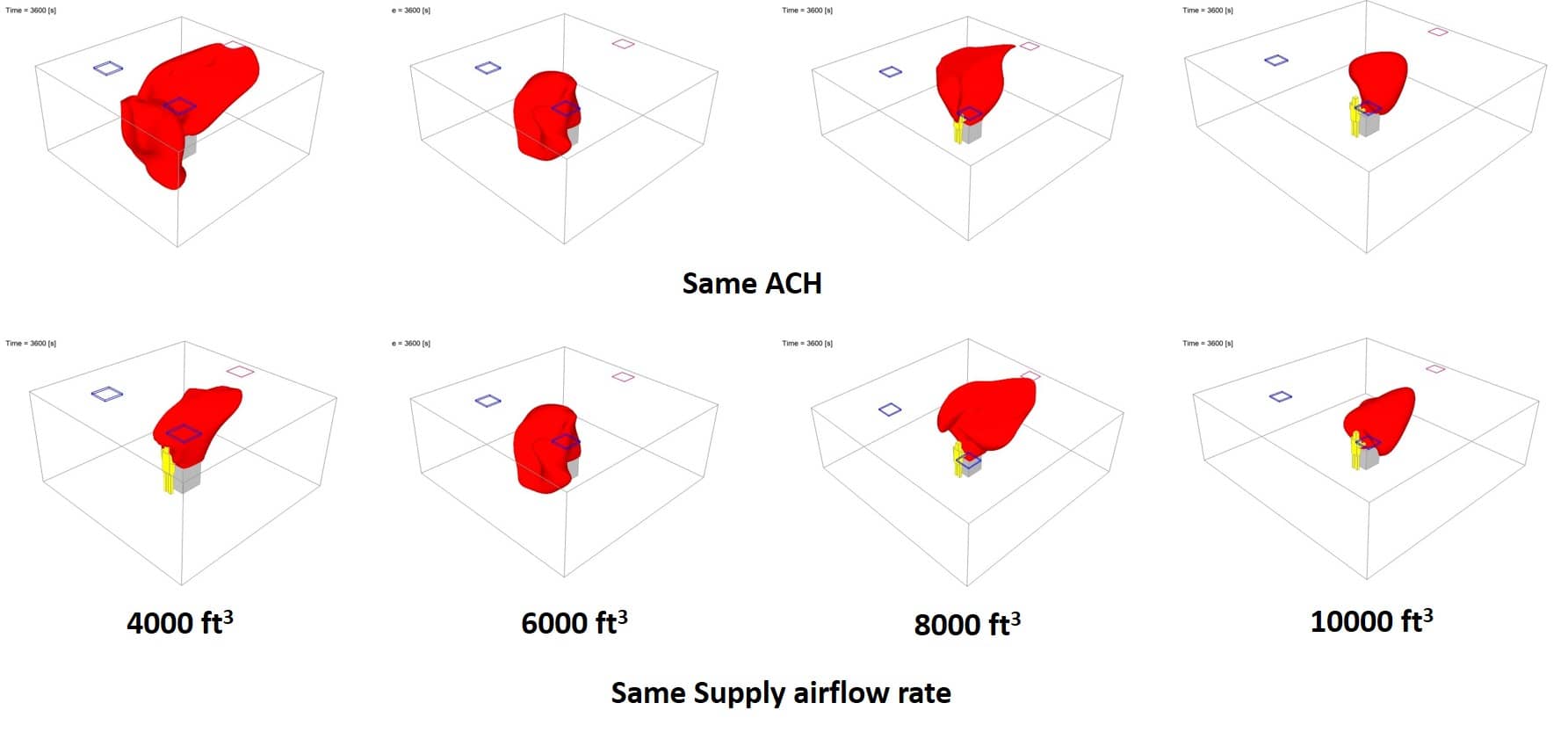

We developed three-dimensional, transient, isothermal CFD models for four different space volumes with identical configuration and contaminant generations rates. We compared the dilution performance of these spaces for the same ACH values with the same supply airflow rates. Two sensors were placed one close to the person’s face and the other in the exhaust grille to monitor the time-varying contaminant concentrations at these locations. With the help of this data, the chemical exposure (dose) for each location was computed. The ventilation performance of each space was evaluated using our newly developed Spread Index. Details are provided in our publication.

Space Volume Matters!

Our CFD analyses indicate that the current practice of specifying the same ACH for all space volumes can make smaller spaces vulnerable to the higher dose of contaminant exposure. By specifying the same supply airflow rates and by proportionately adjusting the ACH with the space volume can maintain a similar level of occupant exposure for all space volumes. CFD analyses show significant spatial and temporal variations in the contaminant concentration and resulting exposure levels. These analyses indicate that the exposure levels in the breathing zone of occupants can be significantly higher than those predicted by the space averaged “well-mixed” conditions. The Spread Index analyses indicate that with the constant ACH approach and due to reduced supply airflow rate the contaminants would reach higher concentrations and spread extensively in smaller spaces than larger spaces. With the volume adjusted ACH approach, such spread can be significantly reduced for smaller spaces and equalized across the space volumes.

Figure 1: CFD analysis predicts contaminant concentration in the breathing zone of occupants. It indicates that the specification of the same ACH for all space volumes would make occupants in smaller spaces vulnerable to higher exposure dose. Specifying the same supply airflow rates instead of the same ACH occupants would experience a similar level of exposure for all space volumes.

Figure 2: CFD analysis predicts the spread of contaminants in a space. It indicates that the specification of the same ACH for all space volumes would increase the spread of contaminants in smaller spaces. Specifying the same supply airflow rates instead of the same ACH can minimize and equalize such spread for all space volumes.

Publication

CFD Analysis of Air Change Rate (ACR) and Space Volume on Contaminant Dilution. Conference paper for the ASHRAE Annual Virtual Conference, July 2020.