CFD Analysis of Demand Control Ventilation for Laboratories

What is Demand Control Ventilation (DCV)?

Often high air change rates per hour (ACH) are specified for laboratories to meet the goal of ventilation. The ACH numbers specified are mostly consensuses based on simplistic approaches of perfect mixing of contaminants with the supply air. It may not be necessary to operate the labs under high ACH all the time. Very few times such as during the accidental spill conditions, the contaminant concentration exceeds the minimum threshold values, and therefore, requires high ACH. For normal operation, the labs can operate at low ACH.

The demand control ventilation (DCV) involves modulating the ACH according to the conditions in the lab. Often the concentrations in the exhaust ducts are monitored to provide feedback to the building’s control system to ramp up or ramp down the air handler fan speed to adjust the supply airflow rates to maintain certain concentration levels. However, the concentration in the exhaust duct may not represent the conditions in the breathing zone of the occupants in the lab. Nevertheless, the DCV can help reduce operating costs, energy consumption, and carbon emissions by modulating the ACH.

Role of Air Change Rates

ACH is defined as a ratio of the total airflow rate into the space to the volume of the space. However, only the supply airflow rate component (the numerator) of the ACH definition determines the extent of dilution in the space. Whereas the volume component (the denominator) of the ACH definition is required only when the rate of purge (removal) is critical as in the case of an accidental spill scenario. Therefore, under most operating conditions when the dilution of contaminants is critical, simply the airflow rate is an appropriate metric for the airflow specification rather than the ACH. Traditionally the supply airflow rates for laboratory spaces are always specified in terms of ACH irrespective of the purpose of ventilation which then yields higher values of ACH.

CFD Analysis of Demand Control Ventilation

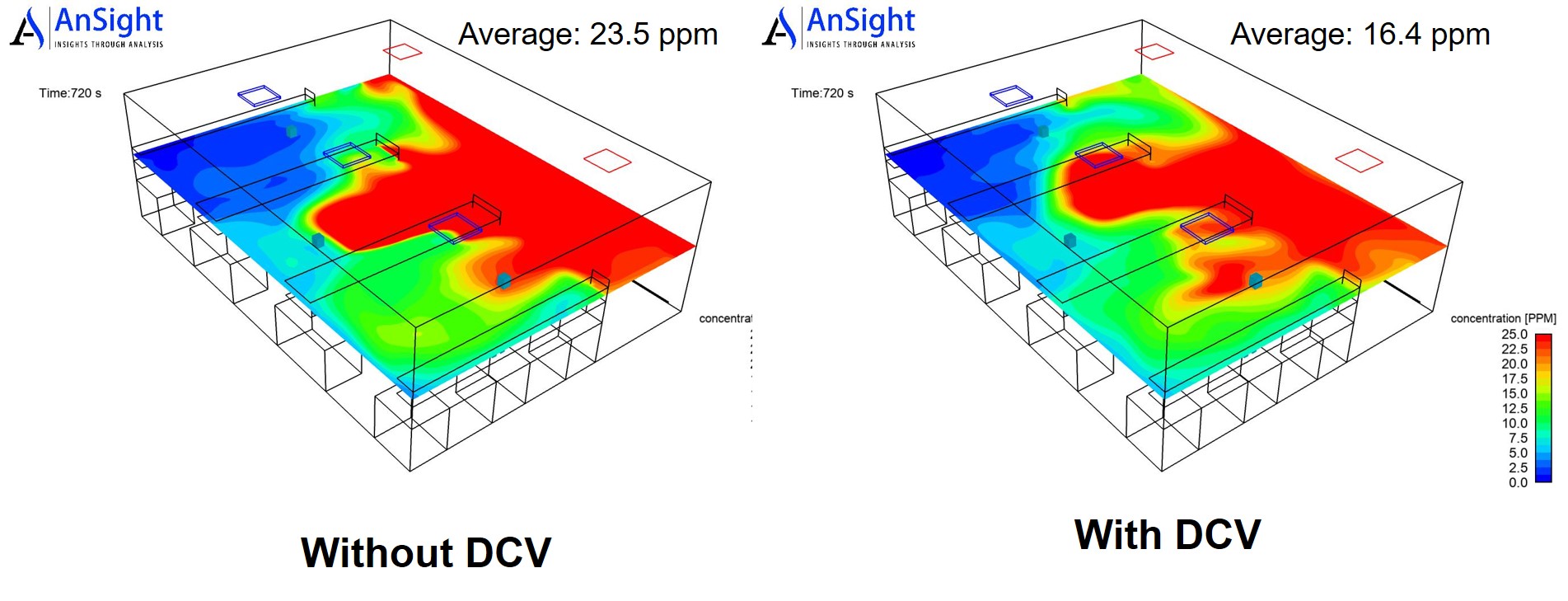

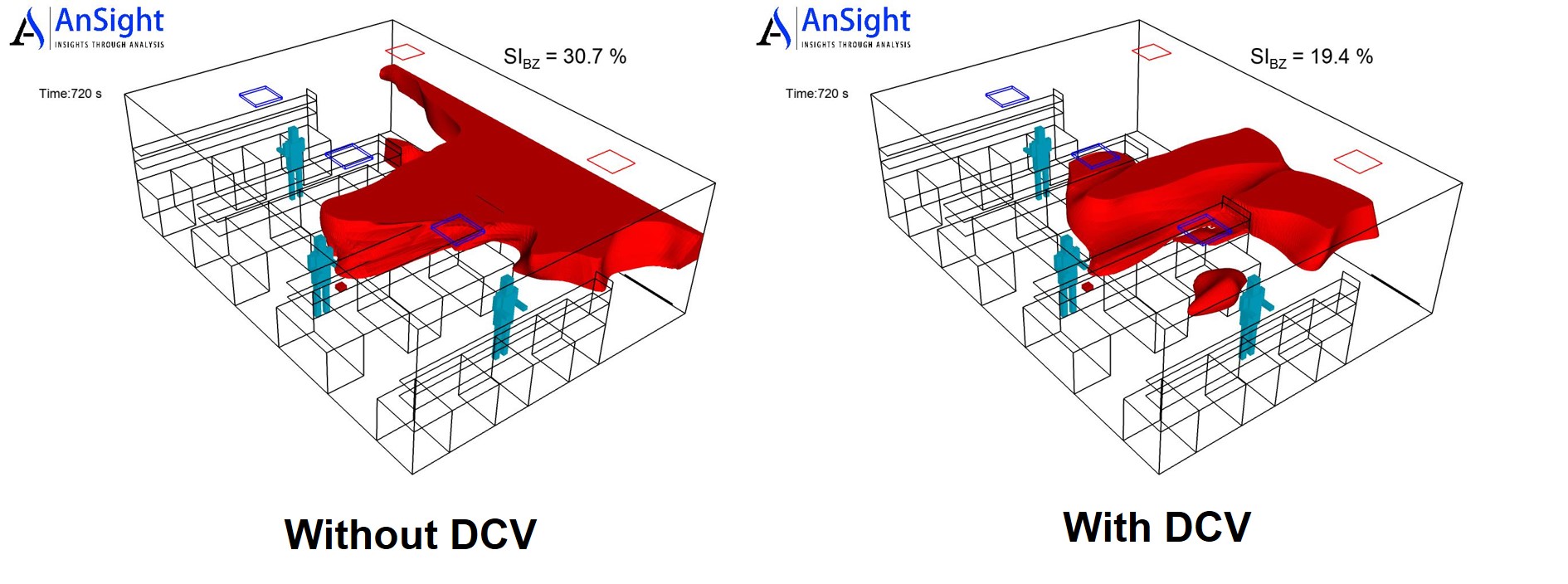

To evaluate the effectiveness of DCV, we have performed a CFD study for an accidental spill scenario in a laboratory. A three-dimensional CFD model was developed to study the transient dispersion of contaminants in a laboratory space under a controlled release of a contaminant. We employed our newly developed metrics of Spread Index (SI) and Purge Time (PT) to evaluate the effectiveness of the DCV system.

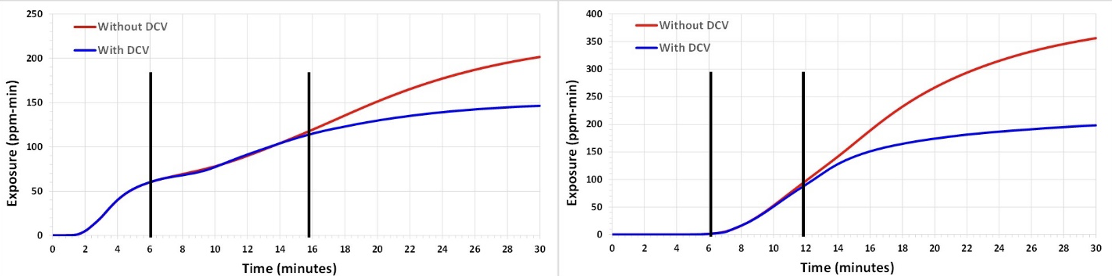

These analyses indicate that the demand control ventilation systems can reduce the time required for recovering the laboratory environment after an accidental spill of chemicals. The Spread Index, which indicates the extent of the spread of contaminants in the breathing zone of occupants, reduced by 37 percent due to the DCV. The Purge Time (PT) – the time required for the ventilation system to bring the concentration levels below a certain acceptable threshold value reduced by almost 7 minutes.

However, the DCV does not show an immediate impact in reducing occupant exposure. The exposure levels either increased or remained unchanged for a long time after the onset of DCV. The benefit of DCV in reducing occupant exposure can be realized mostly during the decay phase after the release of chemical vapors (source) stops.

There are several parameters including the layout of supply diffusers and exhausts; the system lag in starting the DCV system, and the locations of sensors that can impact the effectiveness of the demand control ventilation need further evaluation. CFD can be a valuable tool in analyzing and optimizing demand control ventilation systems.