Aerodynamic Containment Can Reduce Spread of Infectious Aerosols

Building Ventilation and Airborne Transmission of Infectious Aerosols

Air is the primary carrier of heat, moisture, and airborne contaminants including infectious aerosols in indoor spaces. The primary goal of building ventilation is to create a healthy environment for building occupants. It is achieved by supplying clean air to dilute the concentration of airborne contaminants, and thereby, reducing the risk of airborne infection and hazard. The breathing zone of occupants, which is generally between the 4 to 6 feet (1 to 2 m) height from the floor, is the most critical zone in which occupants breathe in and out. The sources of contaminants and receptors both are located in the same zone. The ventilation design should ensure that the clean air is properly distributed in the breathing zone and the contaminated air is effectively removed from this zone.

Why Airflow Patterns Matter?

Indoor airflow patterns play a crucial role in controlling the spread of airborne contaminants. The flow path of airborne contaminants depends on the airflow patterns. Poor airflow distribution in indoor spaces can spread infectious aerosols and make social distancing less effective. The influence of several factors on the performance of building ventilation is complex and often not intuitive. Computational Fluid Dynamics (CFD) analyses help visualize the airflow patterns and the flow path of airborne contaminants and provide valuable insights into the spread of aerosols. CFD analyses, if performed properly with adequate expertise, can help optimize the performance of building ventilation. Such insights gained during the early stages of the design and retrofit process can help reduce the risk of infection in indoor spaces. Distributed supply and distributed exhaust in a space can help in better dilution of the contaminants, provide a path of least resistance for the contaminated air to leave the space, and reduce the probability of infection.

What is Aerodynamic Containment?

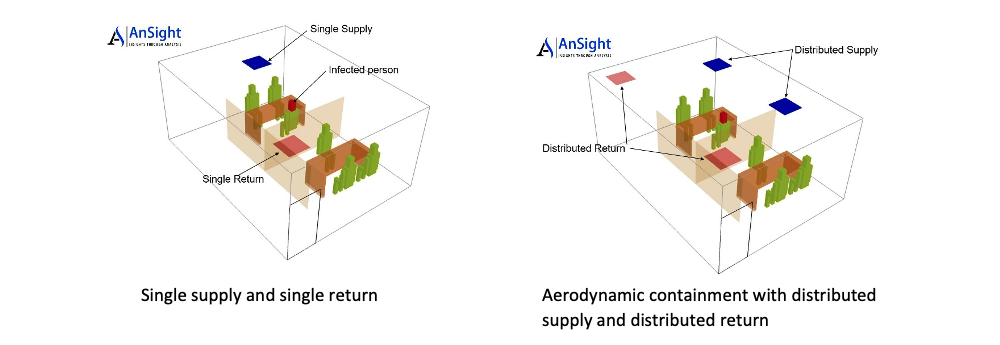

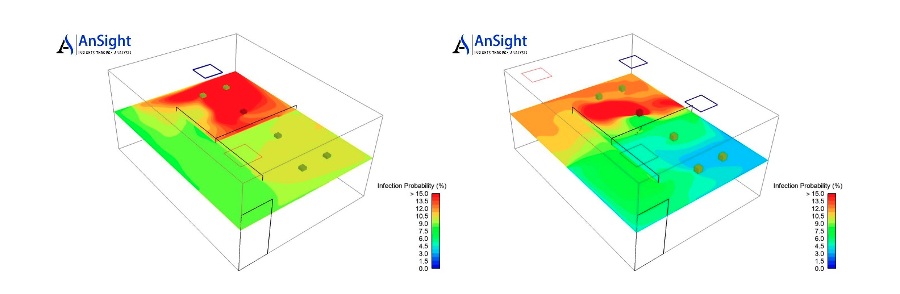

Aerodynamic containment is a symmetric layout of distributed supply and distributed return which limits the spread of airborne contaminants in indoor spaces. Our CFD studies demonstrate that even for a simple layout of a small office with two cubicles, the locations of supply and return air can affect the airflow patterns and the resulting risk of infection for the occupants. A layout with just a single 4-way supply diffuser and a single return grille cannot provide adequate dilution and promote air recirculation and formation of stagnant zones with a high concentration of contaminants.

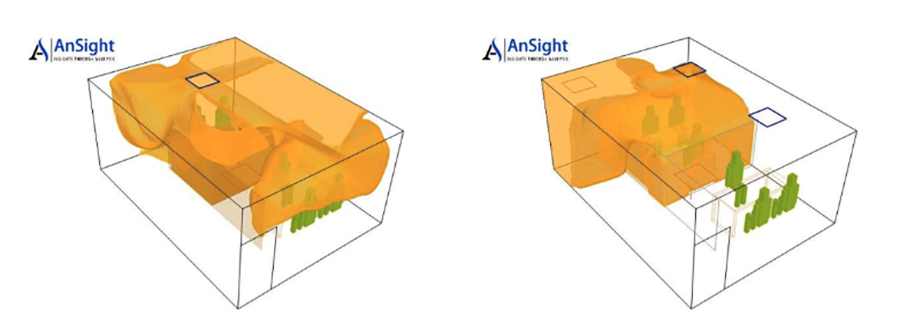

Whereas with the aerodynamic containment, the distributed supply diffusers help in better distribution of clean air; the distributed return grilles provide a path of least resistance for the contaminated air to leave the space, and the symmetric layout of supply and return grilles forms airflow envelopes which promote local containment of the airborne contaminants. Thus, aerodynamic containment can reduce the spread of infectious aerosols, and thereby, reduce the risk of airborne infection in indoor spaces. Since the location of an infected individual in a room is not known a priori, such aerodynamic containment strategy can potentially reduce the risk of cross-contamination.

Figure 1: An illustration showing the difference between a single-supply and single-return layout and the aerodynamic containment layout with two supply and two return locations symmetrically distributed in a space.

Figure 2: CFD analysis shows contours of infection probability computed by Wells-Riley correlation at a breathing plane of occupants. A single supply-single return layout can promote the spread of contaminants and increase the risk of infection. Conversely, the aerodynamic containment layout can reduce the risk of infection by properly distributing the clean air over the occupants and forming a path of least resistance for the contaminated air to leave the space.

Figure 3: CFD analysis shows clouds of the probability of infection of 10 percent and higher. In the case of a single supply-single return layout, the cloud covers all the occupants and almost 50 percent of the room volume. Whereas in the case of aerodynamic containment layout, the cloud shrinks to 36 percent of the room volume and reduces the probability of infection below 10 percent for the occupants in the cubicle which does not have an infected individual.

How to Design Aerodynamic Containment?

Based on our CFD analyses the following guiding principles be used to create aerodynamic containment.

-

- Create a distributed supply layout by increasing the number of supply diffusers (without increasing the supply airflow rate) and strategically placing them over the occupied zone.

- Create a distributed return layout by increasing the number of exhaust outlets to create a path of least resistance for the contaminated air to exit the space.

- Create a symmetric layout of supply diffusers and return grilles to form independent airflow envelopes of supply and return.

Since each space has a unique layout and function, perform CFD analyses to gain insights into the airflow patterns and to optimize the design of aerodynamic containment.