Computational Fluid Dynamics (CFD) Analysis of Laboratory Facilities

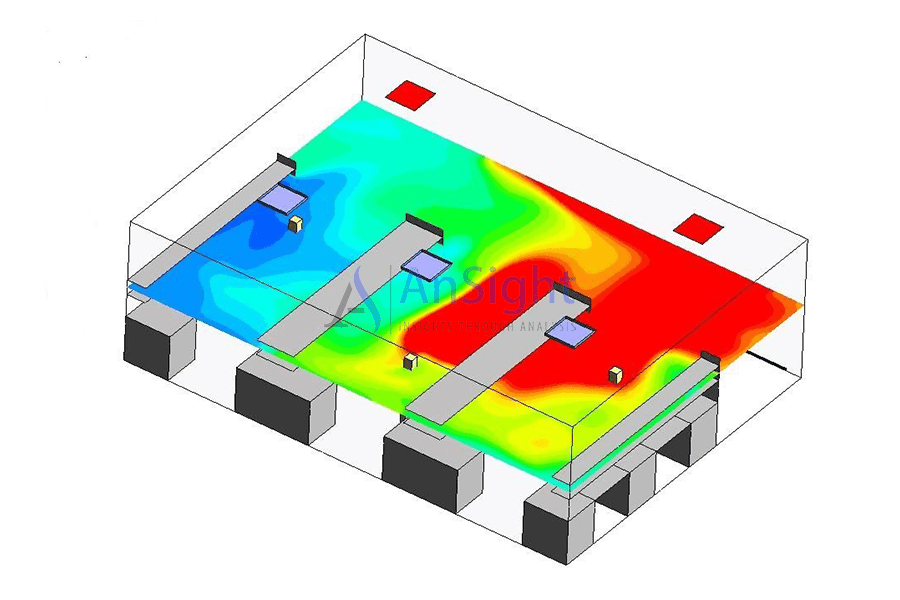

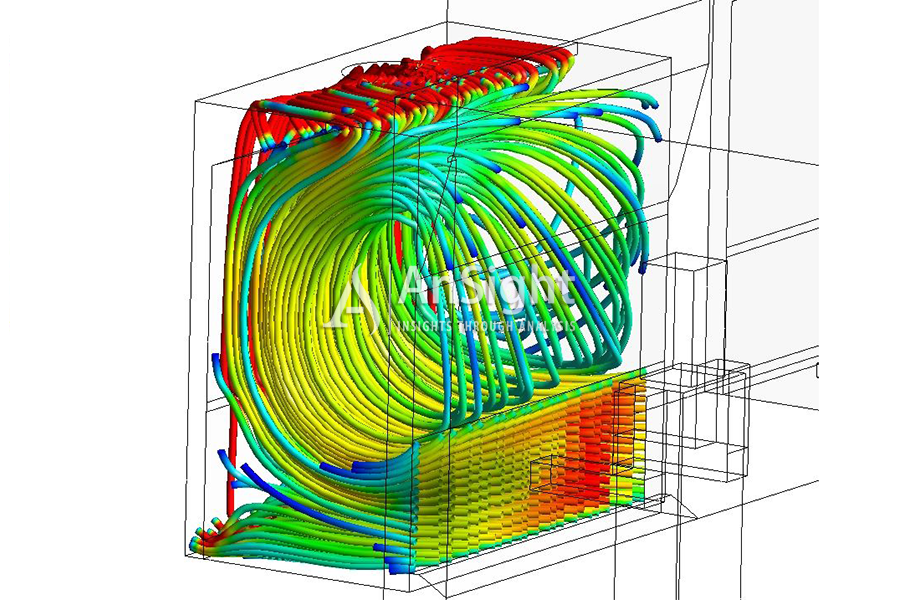

Such well-mixed conditions are rare even in the most simple lab layouts. Our insights demonstrate that not just the air change rates but also the flow path of the supply air play an important role in controlling concentration levels and the spread of contaminants in labs. HVAC configurations including the location and type of supply and exhaust diffusers can significantly affect the flow path of contaminants.

Our proprietary CFD analysis procedures help our clients in risk mitigation due to poor airflow distribution while ensuring people’s safety and comfort. Our analyses help optimize HVAC configuration and lab layout to maximize the ventilation effectiveness using our proprietary CFD based method of Spread Index.

AnSights into Laboratory Facilities

We provide insights into

- Plume dispersion from exhaust stack and cooling towers.

- Optimization of airflow patterns to maximize ventilation effectiveness.

- Three-dimensional distribution of contaminant concentrations.

- Dynamics of contaminant transport and spread.

- Optimization of lab HVAC configuration.

- Optimization of Demand Control Ventilation (DCV).

- Thermal comfort of occupants (ASHRAE Standard 55).

- Active chilled beams.

- Analysis of sensible heat loads on the airflow patterns and occupant comfort.

- Optimization of location and type of supply and exhaust diffusers.

- Optimization of Lab Ventilation Effectiveness (VEL).

Looking for CFD services for Laboratory Facilities?

We have several years of experience in providing optimized solutions for a wide variety of engineering problems involving fluid flow, heat transfer, mass transfer, and other similar engineering processes. If you are looking for an expert who can provide you the right solution with the expert CFD knowledge, feel free to contact us.