Computational Fluid Dynamics (CFD) Analysis of Cleanrooms

Especially for large cleanrooms, maintaining high airflow rates with unidirectional airflow is energy-intensive and cost-prohibitive. The performance and energy efficiency of cleanrooms can depend on several factors such as the strength and locations of particle generation, desired cleanliness level, associated air change rates, and the location and number of supply and air return diffusers in the space.

Our proprietary CFD analysis procedures help our clients to optimize the performance of pharmaceutical, medical devices, biotech, semiconductor, and manufacturing cleanrooms. Our analyses verify compliance with ISO 14644 standards and predict temperature, humidity, pressure, and contaminant levels.

AnSights into Cleanrooms

We provide insights into

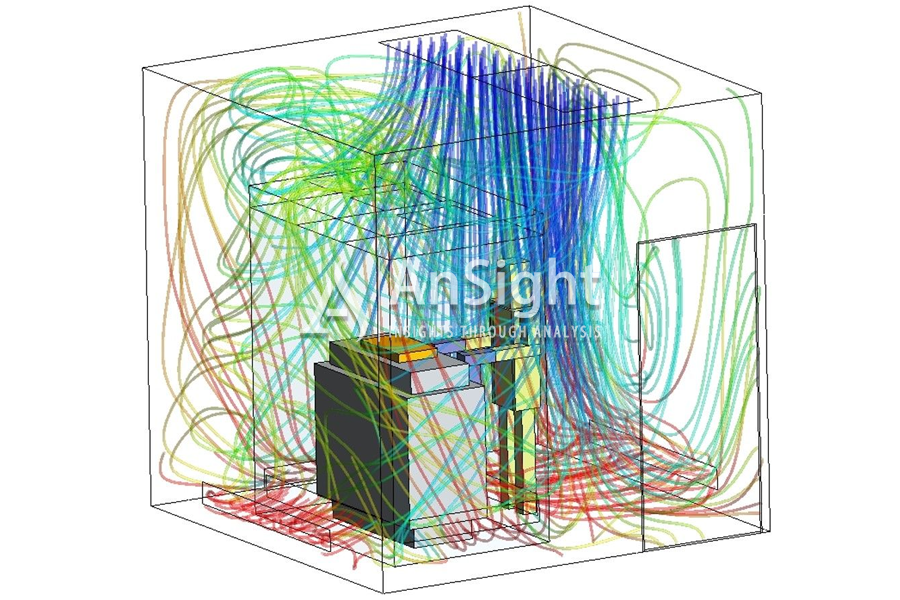

- Analysis and optimization of Particle Removal Efficiency.

- Airflow patterns in the cleanrooms.

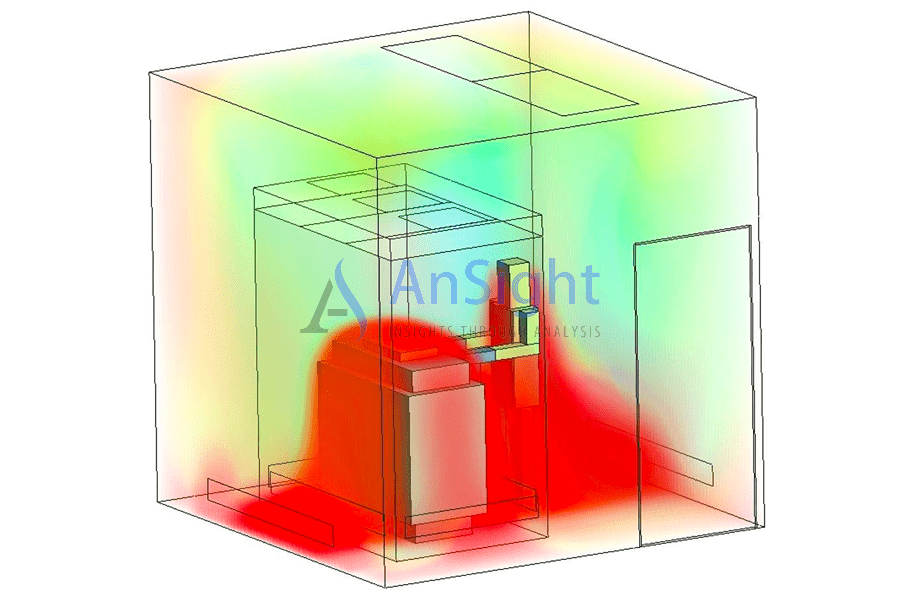

- Distribution of particle concentration.

- Dynamics of contaminant transport and spread.

- Assessment of unidirectional (laminar) flow.

- Optimization of HVAC layout.

- Performance optimization of airlocks

- Optimization of Demand Control Ventilation (DCV).

- Compliance assessment with ISO 14644 standards.

- Effect of location of supply and return diffusers.

Looking for CFD services for Cleanrooms?

We have several years of experience in providing optimized solutions for a wide variety of engineering problems involving fluid flow, heat transfer, mass transfer, and other similar engineering processes. If you are looking for an expert who can provide you the right solution with the expert CFD knowledge, feel free to contact us.